Industrial Turret Milling Machine - Hafco BM-40V

Confirm if additional costs apply

Industrial Turret Milling Machine - Hafco BM-40V : $9,091 AUD ($10,000 Inc. GST)

This mill is in great working order. It was pulled out of a working environment.

Make: Hafco

Model: BM40V

Year: 2016

Manufacturer Description

The BM-40V Industrial turret milling machine is manufactured in Taiwan to a strict precision engineering ultra-high tolerance & superior excellence to cope with many jobs set out by the professional machinist, and importantly to deliver many years of valuable & reliable service.

This medium robust milling machine package is next in the line up from the BM-30A model and is also complete with a few of the most desirable features for example, easy to use variable spindle speed dial, turcite B coated X & Y slide-ways that reduces friction to provide smooth table movement even when loaded up with a heavy job, hardened & ground work table & slide-ways, heavy duty X-axis auto power-feed with adjustable feed stops, 3-axis digital readout system fitted, manual operated oil pump to keep slides in perfect working order and also includes a machine vice & clamp kit set to get you started.

Another reliable feature in this range of precision milling machines is the manufacturing process of the main body & supports, it is made up form the highest quality Meehanite® cast iron. The key to the undisputed success of Meehanite® metals is the rigid application of its patented manufacturing process to provide ultimate strength & durability performance.

To conclude this BM-40V turret milling machine is the most common size machine that’s found in approximately 70% of engineering workshops and when its put to the test it certainly performs its duties with no hesitation.

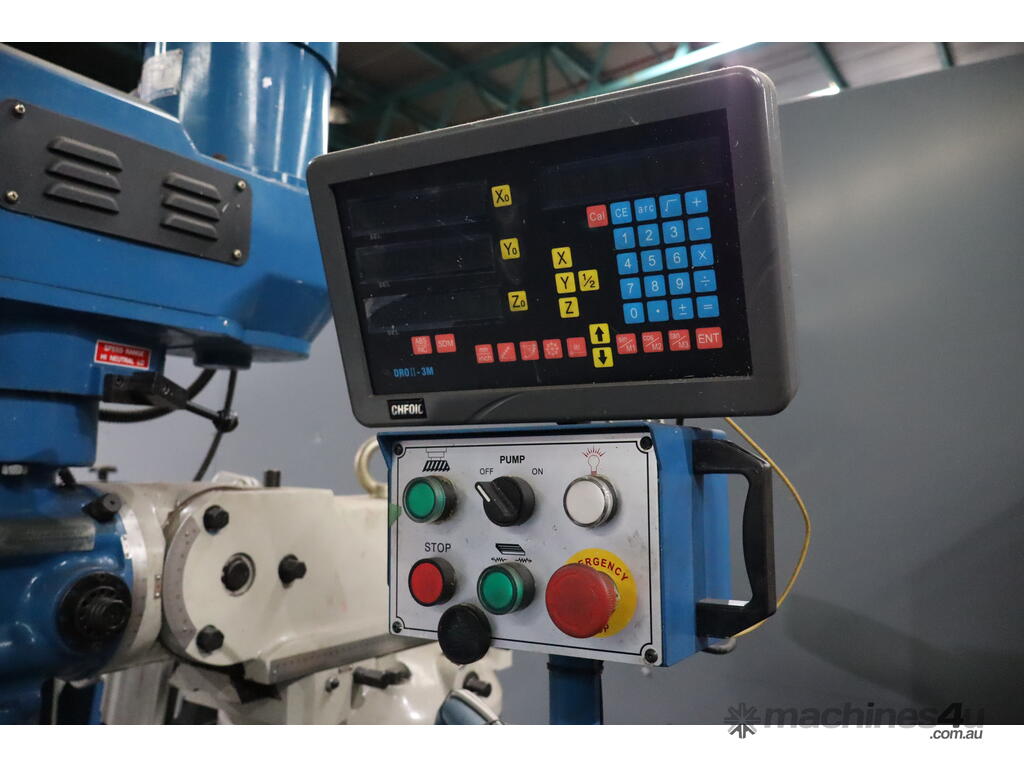

- 3 Axis digital readout fitted

- 3HP 415V motor, dial variable speed system (BM-40V)

- NT30 spindle taper with a chrome & ground quill

- Hardened & ground work table & slide-ways

- Turcite "B" coated X & Y Axis slide-ways reduces friction for smooth operation

- All slides utilise dovetail construction for maximum rigidity

- Meehanite casting for high strength & minimal deformation

- Quality electrics & overload protection in an easy access enclosure

- Horizontal travelling ram mounted on a rotating base allowing repositioning of spindle

- The ram incorporates a tail lug (spigot) to accept a slotting attachment etc.

- High / neutral and low gear selection lever to maximise torque

- Align AL-500S X-Axis power-feed with adjustable micro switch feed stops

- Metric dial graduations 0.02mm for X , Y & Z-Axis

- Automatic quill feed 0.015, 0.04, 0.08mm/rev

- Automatic cut off depth stop on quill

- Oil lubrication pump and reservoir

- Slide-way covers Y & Z-Axis

- Mill head tilts to ±45º forward and back

- Mill head tilts to ±90º left and right

- Manual quick action quill lever

- Mechanical spindle brake

SPECS

Digital Readout: 3-Axis Digital Readout

Type: Vertical

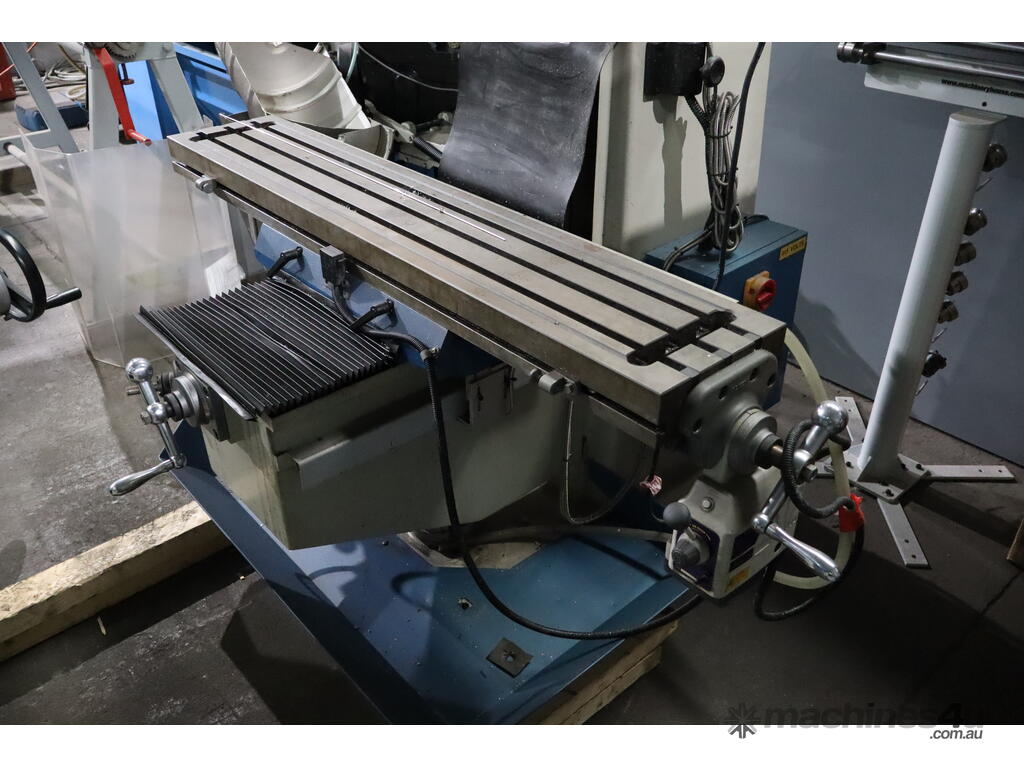

Table Size: 1370 x 254mm

Spindle Taper - Vertical: NT30

Longitudinal Travel (X-Axis): 860mm

Cross Travel (Y-Axis): 360mm

Vertical Travel (Z-Axis): 425mm

Type of Slides: Dovetail

Ram Travel: 508mm

Spindle to Table: 505mm

Spindle Travel / Diameter: 127 / 86mm

Throat Depth (max.): 735mm

Tilting Head (Left ~ Right): ±90º

Tilting Head (Forward ~ Back): ±45º

Power Feed - Quill (mm/rev): 0.015 / 0.04 / 0.08

Power Feed - Longitudinal (X-Axis): 20 - 2000 mm/min

Table T-Slot Size: 8mm

Work Table Load Capacity: 300kg

Spindle Speeds Vertical: Variable (70 - 3500 RPM)

Motor Power - Vertical Spindle: 2.2kW

Voltage: 415V

Weight: 1000kg

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print